Energy independence in the industry with a CHP plant

Sustainable industrial CHP plant

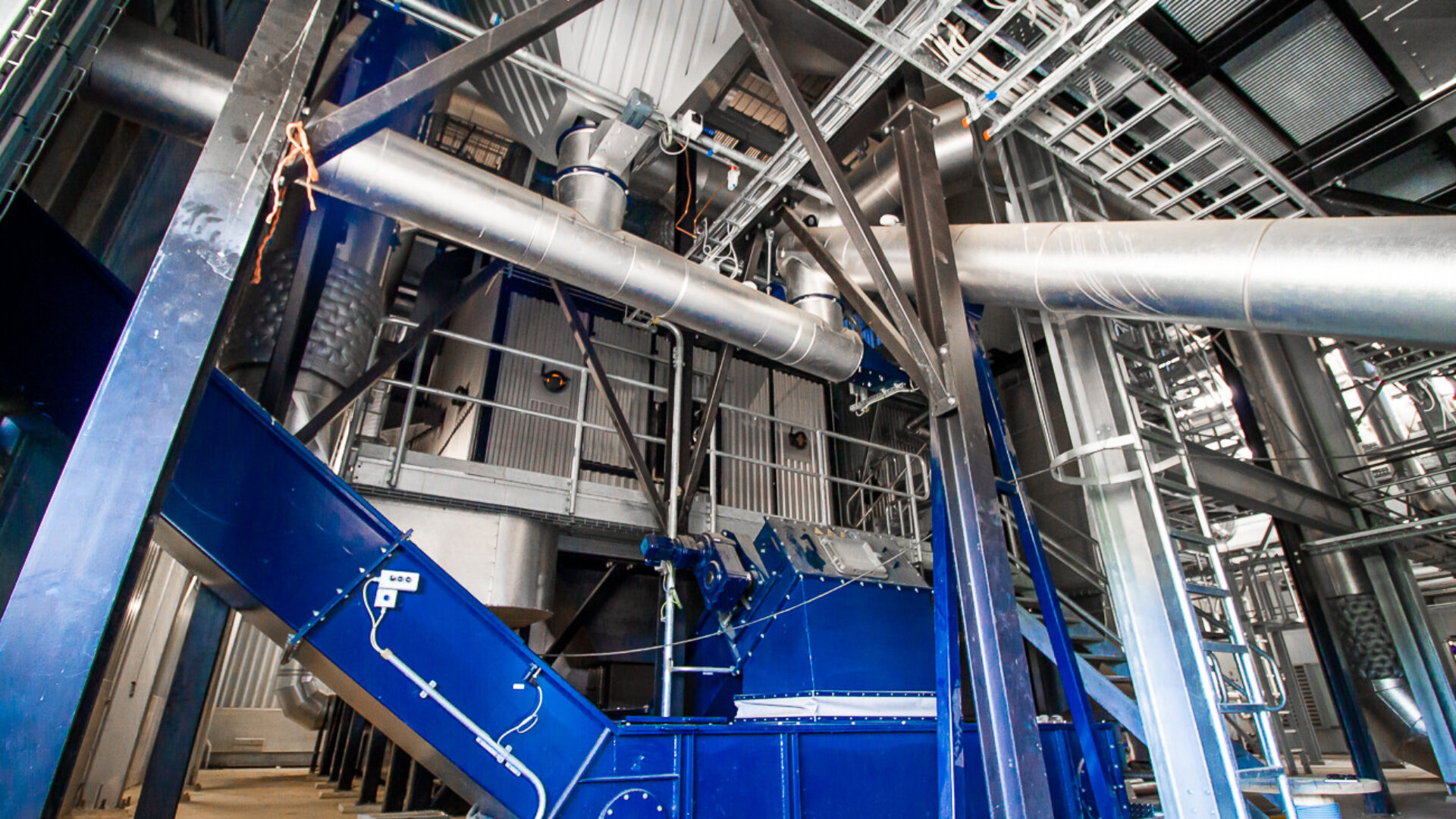

HoSt realizes small and medium-sized industrial CHP plants, also known as cogeneration plants, in the range of 1MWe-10MWe to produce renewable energy and as a replacement for fossil natural gas consumption. These can be fired with low grade wood waste, such as fresh wood waste, wood from composing systems and waste wood from pruning. But also with refuse derived fuel (RDF) or agricultural residues. Built compact with a low building height and with the lowest emissions in the industry, these type of CHPs have the highest social acceptance. CHP plants bring a bright future to the industrial energy demand.

While the Netherlands is known for the lowest emission limits in Europe, HoSt takes it a step further and developed a feasible thermal conversion technology that enables CHPs to reach significantly lower values than the most stringent emissions limits.

“With a CHP system, fired with biomass or waste, it is possible to have pre-pandemic heating prices”, says HoSt Group.

Carbon Capture

Biomass-fired heat and power plants can be equipped with a carbon capture system to reach CO2 negative. An installation fueled with RDF will reach carbon neutral with the addition of carbon capture technology, depending on the biomass content in the fuel. Carbon capture technology provides circularity, creates additional income, and produces a sustainable product.

Energy as a Service

Besides offering combined heat and power plants, HoSt offers heat and electricity as a service (Energy as a Service) for industrial customers, utility companies, as well as for greenhouses or greenhouse clusters, boosting the energy transition. For this model, a long-term heat (and optional electricity) off-take agreement is the basis of the partnership. HoSt will further take care of all other elements: like the fuel supply, investment, building the plant and of course O&M

Renewable process steam: a business case

As example: what does the business case look like for a steam demanding factory in Europe? Let’s assume this factory considers switching to a 15 MWth biomass- or RDF-fired CHP plant with a flue gas condenser. In this example, the factory consumes 75.000 MWh of steam per year at 6 bar and 55.000 MWh of hot water for its processes. Both are generated with a natural gas boiler without electricity generation.

With a controlled extraction turbine, HoSt can generate approximately 2.25MWe (15% electricity of the boiler capacity) for this case. Currently, the predicted gas prices for 2023 are well above 100euro/MWth. Let’s assume 60 euro/MWh as an average for the years after 2024. For electricity, the prices for 2022 are well above 250 Euro/MWh but let’s also assume for the years after 2024 an average of 150 euro/MWh.

When using these basic key metrics in a business case, the heating price for biomass is around 30% cheaper than gas and for RDF more than 60% cheaper without any subsidies from the government.

Do you want to know more about how a biomass or waste-fired CHP can lower your energy prices for heat and electricity, or would you like to receive a quotation for your project, please don’t hesitate to contact us.