Biogas plants

Biogas plant solutions

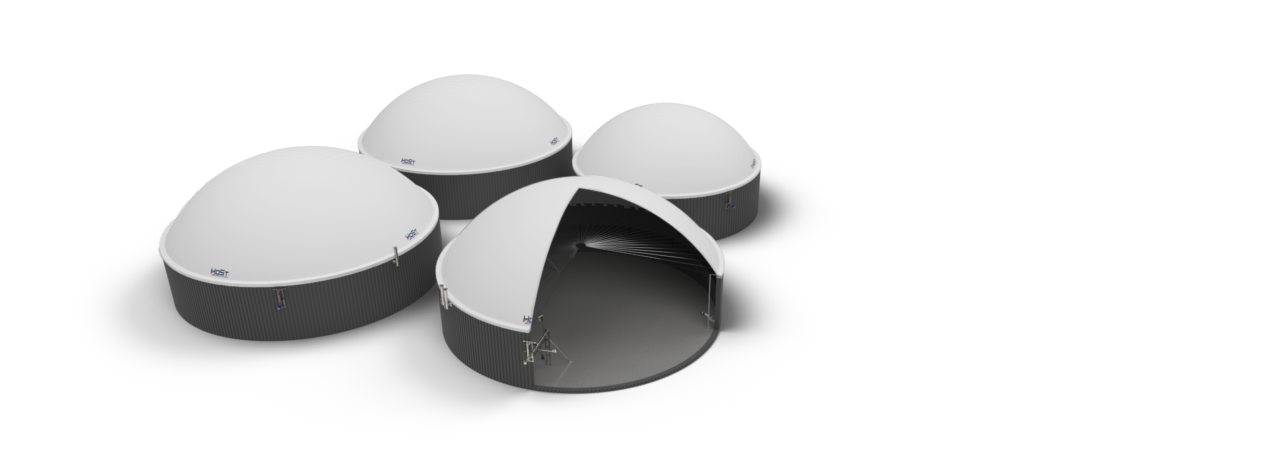

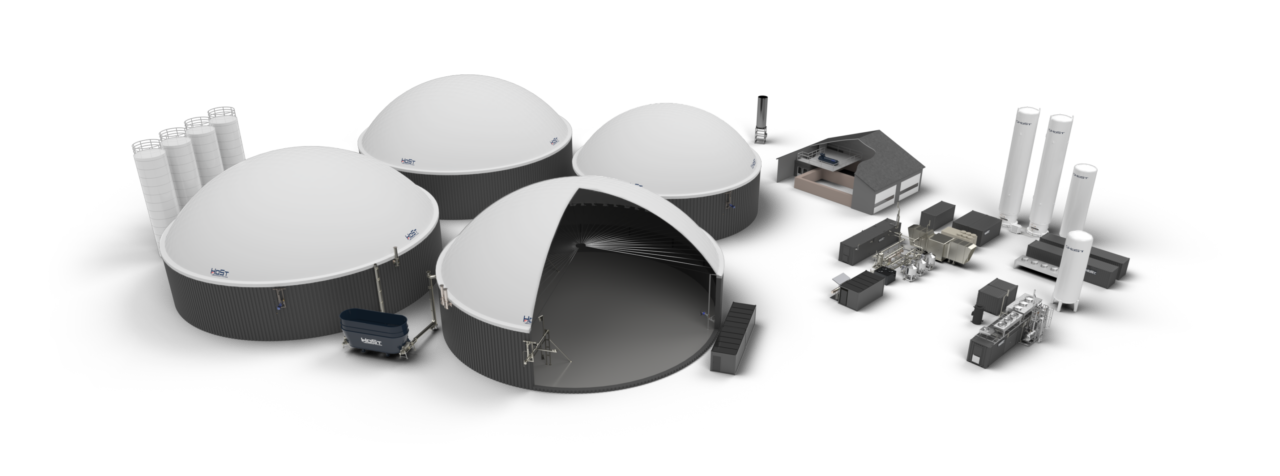

Our turnkey biogas plant solution

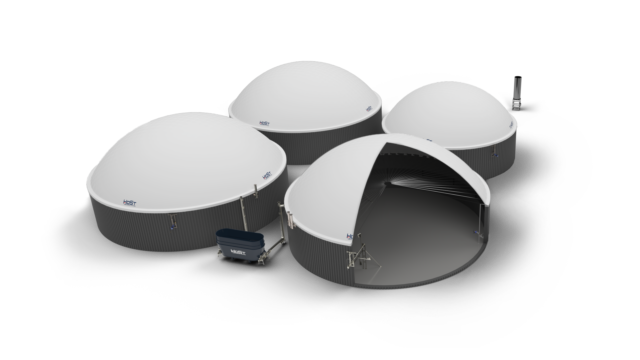

Our biogas plants can be supplied with in-house biogas upgrading, bio-LNG, bio-CNG, and CO2 liquefaction technology. The image below is an illustrative representation.

Biogas production

Innovation and research are high priority at HoSt, leading to a constant optimization of our anaerobic digestion technology and our biogas plant design. This translates into robust biogas plants suitable for all types of feedstock and repowering of biogas plants. Repowering ensures high efficiency and maximizes the potential of the existing biogas plant.

Advantages

Contracting flexibility

HoSt provides flexibility in contracting, which translates to turnkey biogas plants or a reduced scope consisting solely of engineering and key components. With our flexibility in contracting, we can meet any requirements your project may have. Therefore, we can customize technologies to preferred criteria and guarantee the ideal implementation of the biogas facility.

Biogas plant calculator and configurator

A successful biogas project starts with the biogas plant configurator from HoSt. This innovative tool provides comprehensive mass and energy balances tailored to your unique needs. Additionally, the biogas plant calculator takes the Carbon Intensity score (CI-score) into account. With the biogas configurator we can perform calculations for biogas plant projects. For increased profitability of the project, the calculator provides professional advice on feedstock configuration and offtake services. Resulting in the best Total Cost of Ownership (TCO) for your project, the lowest CO2 footprint, and the highest possible revenue.

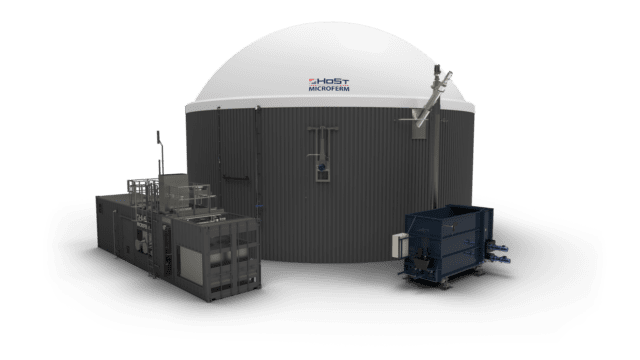

Biogas from sugar waste

This biogas facility at Fontenoy, Belgium transforms beet residuals, such as beet tops, into renewable energy. After the first successful project for Iscal, HoSt has developed a second biogas plant. The biogas plants efficiently process up to 200 tons of waste daily during the sugar beet campaign. After a pretreatment, the biogas is directly applied in Isera & Scaldis’ sugar production process which contributes to sustainable sugar manufacturing and a greater independency of fossil natural gas. Aligning organic waste production with the factory’s heat demand.

We realized biogas plants for