Digestate treatment

Sanitation

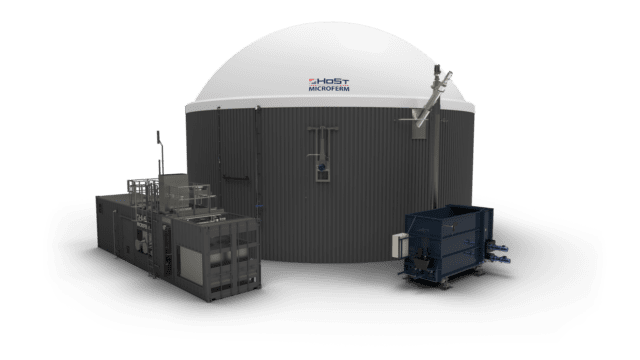

Depending on the type of feedstock, sanitation of the feedstock may be required, feedstocks such as slaughterhouse waste or food waste. The sanitation technology is tailor-made and designed to meet project specifications. With the option of different temperatures (55, 70, or 130 degrees) and tank sizes. Together the customizable technologies lead to the ideal approach for every project.

Digestate treatment is applied in the following turnkey solutions

Features

- Possibility of sanitation at different temperatures

- Different tank sizes

- Heat recovery after sanitation

Digestate separation

Digestate is a by-product produced through the anaerobic digestion process. After pasteurization and with digestate treatment technology, the digestate can be separated into two fractions – solid and liquid fractions. Separation can either be done with the screw press technology or with a decanter technology. If required, additives can be added to further enhance the separation of nutrients and organic matter.

Application of digestate

After the separation, the liquid fraction of the digestate can be applied to the field. If desired, the liquid fraction can be further treated with ammonia stripper for the production of ammonium sulfate. The separation of digestate improves further processing and usability as a bio-fertilizer, based on the requirement of the digestate, the most suitable technology will be selected.