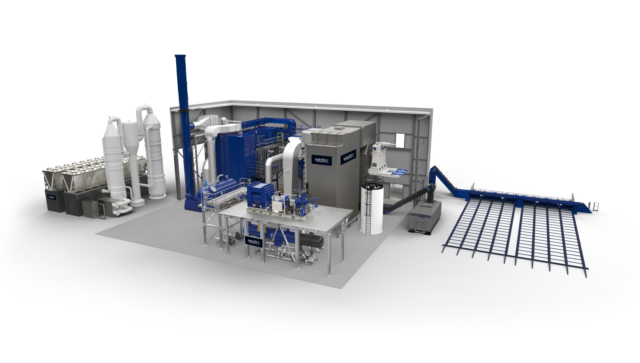

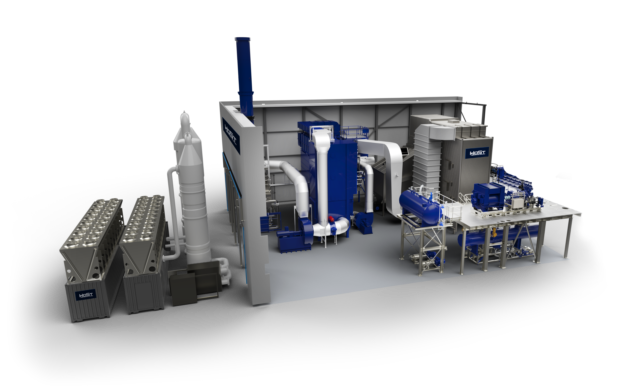

Steam turbine technology

Electricity & steam

A steam turbine is an important component in a combined heat and power plant, converting biomass, RDF/SRF, or waste into electricity and/or steam. We apply only high-quality and robust steam turbines, either single-stage or multi-stage, action, or reaction turbines in our heat and power plants. This ensures an optimized turbine for your business case and application. The steam turbine also serves in steam production. Steam can be directly supplied from the turbine exhaust (working on a backpressure mode) to processes that require a certain pressure or can be extracted at a fixed pressure from a controlled extraction. For heating networks, we can supply a turbine that works in a condensing mode, optional with a controlled extraction for process steam.

Steam turbine technology is applied in the following turnkey solutions

Features

- Single-stage or multi-stage steam turbine

- Action or reaction type of turbines

- Controlled steam extraction

- Back pressure or condensing turbines

- Steam condenser for higher efficiency

- High-quality and robust design

High electrical efficiency

The electrical efficiency of the steam turbine is directly influenced by the conditions at the inlet and outlet. Specifically, higher inlet superheating temperatures result in a more efficient steam cycle, making effective use of the steam produced in the boiler to drive the turbine. High-pressure steam enters the turbine and which in turn drives the coupled generator to produce electricity.

Seamless process integration

Maximum electrical output is achieved through the interplay of high-pressure steam, an efficient steam turbine, and seamless process integration. Additionally, the efficiency scales with the condenser’s heat output temperature; lower hot water temperatures and/or lower pressure of the process steam result in increased electricity production.