Boiler technology

Industrial boiler design

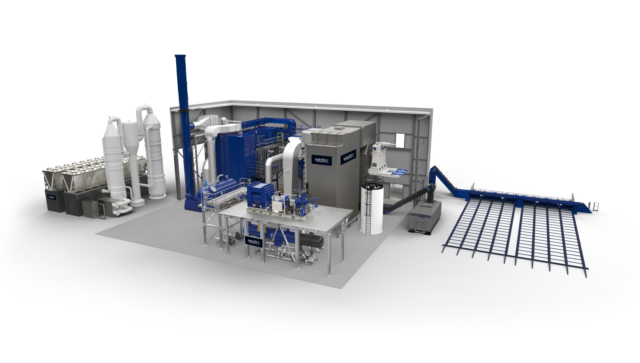

We utilize robust industrial boilers for fuel sources ranging from biomass to RDF/SRF and waste. These boilers are placed downstream our firing grate and furnace and are engineered for maximum uptime, efficiency, and reliability. Key advantages include minimized production stops and a design that effectively addresses avoiding of fouling, both through its design and through online cleaning with soot blowers. The HoSt water tube boiler can run a whole year without a need for a maintenance stop. Additionally, their compact size, self-supporting boilers and quick installation process further contribute to operational efficiency and reduced downtime.

Boiler technology is applied in the following turnkey solutions

Advantages

- Automatic online cleaning system minimizes boiler fouling

- Minimized production stops

- Compact & quick installation on site

- Easy transport: Our modular boilers are road-friendly

Boiler type

In our heat and power plants, we use water tube steam boilers for electrical capacities from 1-10MWe. For CHP from 1-2MWe we can also offer a CHP unit with a fire tube steam boiler. In our hot water boiler plants, we use vertical placed fire-tube boilers. For large hot water boilers or boilers for waste wood, or fuels with high salt/ash content we supply a combi boiler with a large empty first draft.

Technical highlights

- Vertical water tube boiler in heat and power plants & steam boiler plants

- Cilindrical fire tube (or combi) boiler in hot water boiler plants and our smallest biomass CHP plants

- RDF / waste fired boilers are IED compliant and equipped with 2s retention time on 850°C.

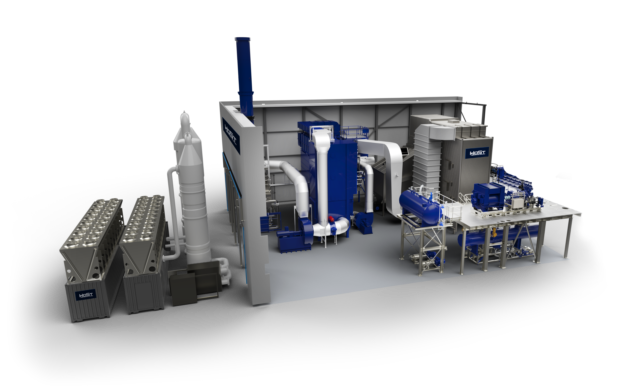

- The water tube boilers are designed to fire the lowest grade fuel available and to withstand high ash, salt, clorine and sulphur contents in the fuel

- Water tube steam boilers up to 90bar and 480°C

Water tube steam boiler

In HoSt’s heat and power plants fueled by biomass, RDF/SRF, or waste, we use a specialized three-pass water tube steam boiler positioned behind our moving grate furnace. Hot furnace gases create high-pressure steam in the boiler, which turns a turbine to generate electricity. Our water tube boilers are engineered to fire the lowest grade fuel while effectively handling high levels of ash, salt, chlorine, and sulfur present in the fuel. We offer water tube steam boilers that can operate at pressures up to 90 bar and temperatures as high as 480°C.

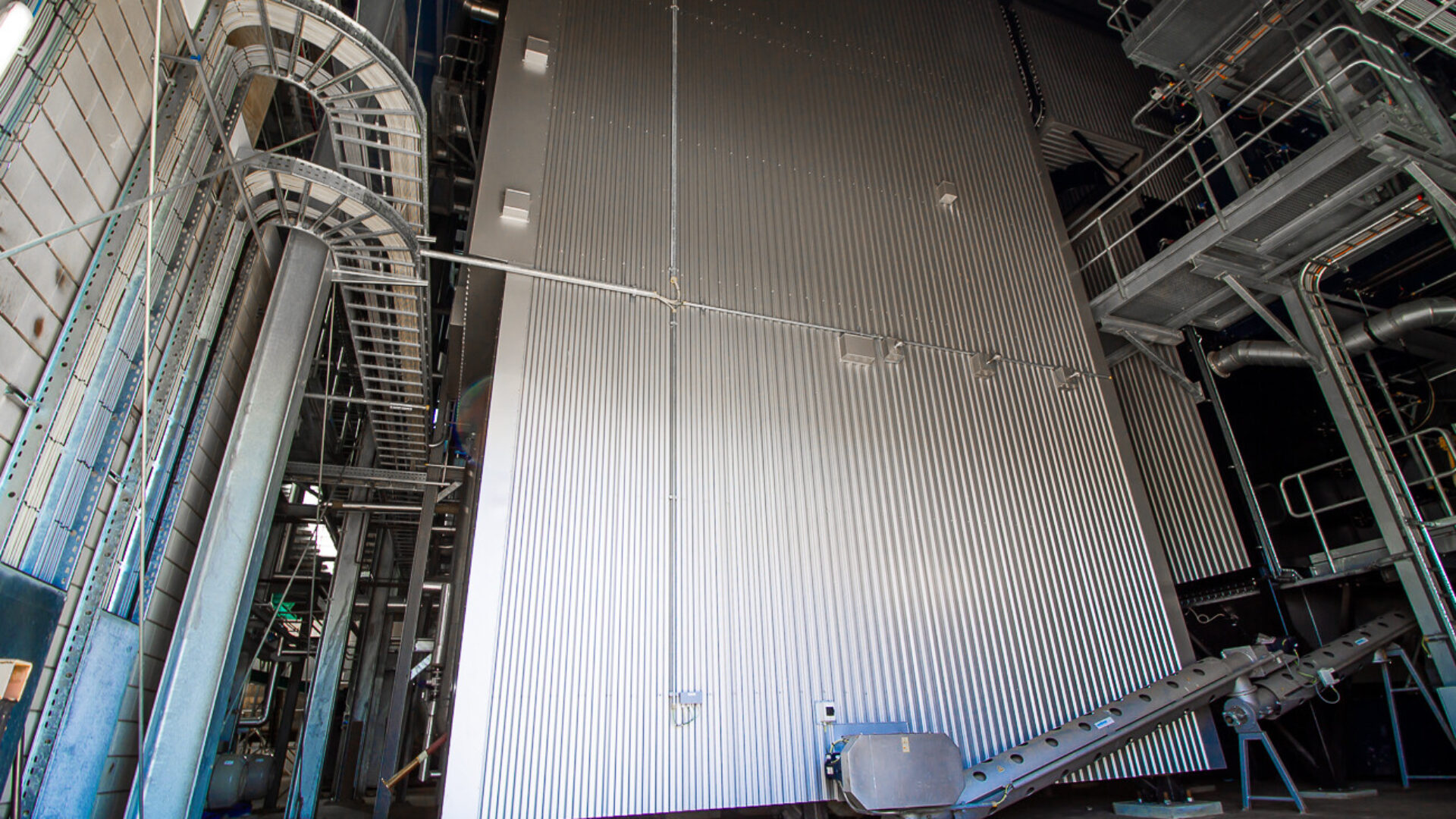

Hot water boiler

In our hot water boiler plants, we apply a vertical fire-tube boiler, for larger capacities or if fuels with a high ash content are fired, we offer a combi boiler with an empty radiation draft before entering the fire tube boiler. An automatic and online soot blowing system easily removes the soot, increasing the reliability and uptime of the whole setup. The cooling of hot flue gasses with radiation is key to achieve a high uptime of the plant due to prevention of sticky ash fouling the convection parts of the boiler. A vertical placed boiler has a higher uptime than a horizontal placed boiler because ash will fall down by use of gravity instead of settling in a horizontal placed boiler.

Cylindrical fire-tube steam boiler

In our lower range of steam boilers and CHP we offer a fire-tube steam boiler. This type of boiler has a competitive pricing and is easy to operate and can be offered in the range of 8-15MW and up to steam pressures of 25bar. Flue gasses from the furnace flow through the first radiation draft of a fire-tube boiler and then through two convection passes and ultimately through an economizer. An automatic and online soot blowing system easily removes the soot, increasing the reliability and uptime of the whole setup. The cooling of hot flue gasses with radiation is key to achieve a high uptime of the plant due to prevention of sticky ash fouling the convection parts of the boiler.