Anaerobic digestion

Biogas production through anaerobic digestion

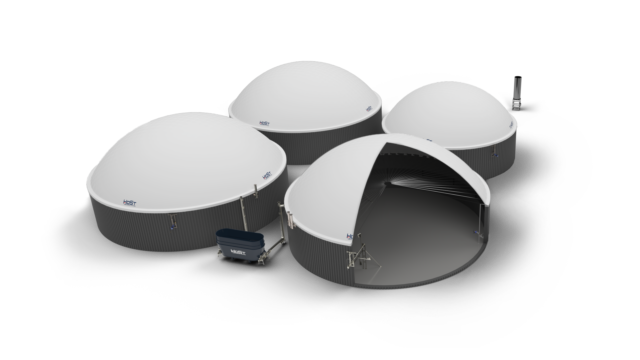

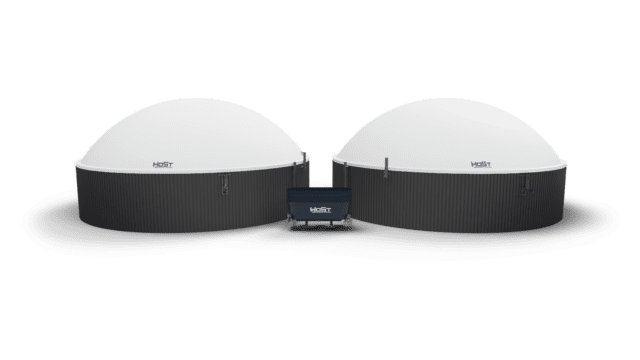

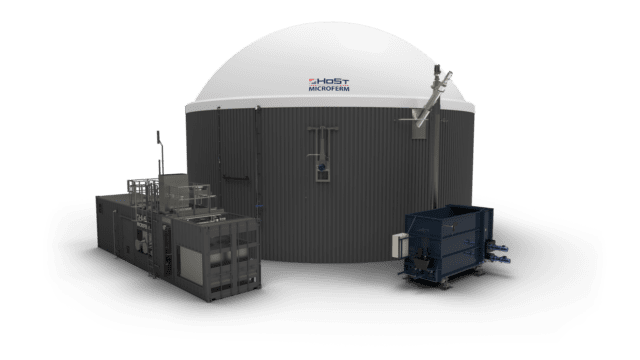

Anaerobic digesters from HoSt achieve high process stability, availability, and conversion. Due to our enhanced mixer configuration, our anaerobic digesters can operate with a high dry matter content, resulting in increased output per m3 (ft3) reactor volume and lower investment costs. Moreover, the risk of silt build-up, drifting layers and foam layers is minimized. The digesters feature in-tank H2S removal, heat recovery, and patented double membrane roofs further decreasing operational costs. Additionally, Greenstep technology enhances biogas production and the mixability of the digester.

Anaerobic digestion is applied in the following turnkey solutions

Features of HoSt Anaerobic Digesters

Our anaerobic digesters incorporate novel engineering that by themselves are good, but combined are powerful and work to lower carbon-intensity (CI) scores:

- Patented double insulated membrane roofs

- Proprietary in-tank H2S removal

- Ability to run on high dry matter content in the digester

- Robust plants due to high-quality equipment

- External heat exchanger

- Advanced mixing system with fixed position and external parts

- Automatic anti-foam system

- Triple insulation that requires less biogas for heating

- Easy to operate due to in-house developed software

AD technology

For optimal flexibility, HoSt offers various Infeeder systems. The most suitable system for the project is chosen based on the type of feedstock. Solid feeders are typically placed on weighing cells to ensure precise product input. Furthermore, HoSt offers different types of liquid storage tanks with the best option selected based on customer preference, waste type, and local climate. These tanks can be heated, insulated, and are available in various capacities. HoSt has globally constructed numerous AD plants using different feedstocks across various industries.